SOLIDWORKS VS MASTERCAM SOFTWARE

It's like every time they decide to try something new, they create a version or two which are absolutely broken, and if you lack the patience to wait or haven't paid maintenance when they finally fix it, you'll just be stuck with broke-dick software and no support. Mastercam just leaves its users in the lurch whenever they release a new version.

SOLIDWORKS VS MASTERCAM UPDATE

You have to choose between the older, more mature products and the newer, often easier to use but less full-featured options.Ī lot of people are going to be upset when they see how different the next generation of Esprit is, but DP are absolutely brilliant for continuing to update the 20XX legacy version as they develop TNG. These aren't easy problems to solve, and the market is not large enough to enable huge development budgets.

They are both old pieces of software with tons of legacy bullshit nobody has the guts to throw away and start over with, except for when they do throw things away, which pisses off the long-time users. If you are looking to post a job opening, our only requirement is that you post the salary or hourly wage of the job posting. It certainly outstrips Fusion in the level of control you have over tool pathing. Mastercam has been around for some 30+ years and is a very mature product. Fusion 360 Ultimate which has (or will have 4 and 5 axis simultaneous machining) is 1,200.00 per year. If you see a pic that isnt tagged please report. To purchase a subscription its 300.00 per year.

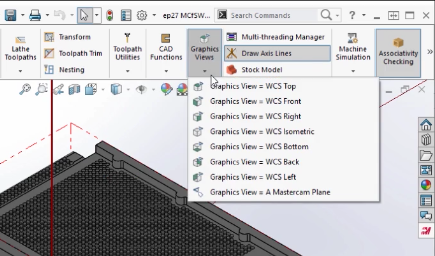

SOLIDWORKS VS MASTERCAM CODE

We are, by default an adult community but plenty of adults are squeamish. CAM allows you to take a part designed in a program like Solidworks (CAD), and convert it into G code for a CNC to produce. Be it machine gore or how you sliced your finger off on a bandsaw. Posting gory or gruesome pictures is totally fine. If you see this behavior taking place in a thread, please report it so that the moderation team can remove the offending posts. I have found Fusions tool paths are better, but dont give the level of customization that MC, but overall ease of use and the fact that you can share work on the shop floor, free post, the cost, and the fusion. You don't have to like the way that someone else drills a hole, but there is absolutely no reason to personally attack, harass or insult another user. Youre so used to MasterCAM and its bullshit machining strategy, that you dont like the 'complicated' tool path HSM gives you, even though its faster, easier on the tool, and more efficient. But 6000 plus holes in a part are not everday use for most people. Have some pride in your specialty, and set your flair on the sidebar to declare your area of expertise!īe polite.

Just remember to wash your hands before and after you go to the bathroom.įor anything tooling related, from belt grinders to Bridgeports to CNC programming.

0 kommentar(er)

0 kommentar(er)